Are you struggling to find the perfect epoxy resin for your next project?

You’re not alone.

Many crafters and DIY enthusiasts face this challenge.

But fear not, because this guide will help you navigate the world of epoxy resins with ease.

Epoxy resin is a versatile material used in countless applications, from crafting to industrial coatings.

Its popularity stems from its durability, clarity, and ease of use.

But with so many options available, how do you choose the right one?

Let’s dive in and explore the fascinating world of epoxy resins.

What is Epoxy Resin and How Does it Work?

Definition of Epoxy Resin

Epoxy resin is a type of thermosetting polymer.

It’s composed of two main components: the resin and the hardener.

When mixed, these components undergo a chemical reaction called curing.

This process transforms the liquid mixture into a solid, durable material.

The Chemistry Behind Epoxy Resin

At its core, epoxy resin contains epoxide groups.

These are three-membered rings consisting of one oxygen atom and two carbon atoms.

The epoxy groups react with the hardener to form a cross-linked network.

This network gives epoxy its strength and chemical resistance.

Epoxy monomers are the building blocks of the resin.

They can vary in molecular weight and structure.

Low molecular weight epoxy resins are often liquid at room temperature.

Higher molecular weight epoxy resins tend to be solid.

Curing Process: How Epoxy Resin Solidifies

The curing process is where the magic happens.

When you mix the resin and hardener, you initiate a polymerization reaction.

This reaction creates strong chemical bonds between the molecules.

As the curing progresses, the mixture becomes more viscous.

Eventually, it transforms into a solid material.

The curing time can vary from minutes to days.

It depends on the specific epoxy resin formulations and curing conditions.

Some epoxies cure at room temperature.

Others require heat or UV light to fully cure.

How to Choose the Right Epoxy Resin for Your Project

Choosing the right epoxy resin can be tricky, but it’s all about understanding what you need. If you’re making surfboards, you need something used to cure epoxy resins quickly. For serious stuff, like in the used in aerospace industry, you’ll want the top-quality, heat-resistant type. Always read the labels and match them to your project’s demands!

Types of Epoxy Resin and Their Uses

Not all epoxy resins are created equal.

There’s a wide range of epoxy resins available, each with unique properties.

Coating epoxy is ideal for creating smooth, glossy surfaces.

Casting resins are perfect for molds and deep pours.

Epoxy adhesives excel at bonding various materials.

Cycloaliphatic epoxy resin offers excellent UV resistance.

Choosing the right type is crucial for your project’s success.

Factors to Consider: Hardener, Cure Time and UV Resistance

When selecting an epoxy resin, consider these key factors:

- Hardener type: Different hardeners affect the final properties.

- Cure time: Fast-curing epoxies are great for quick projects.

- UV resistance: Important for outdoor or sunlight-exposed applications.

- Viscosity: Affects how easily the resin flows and self-levels.

- Clarity: Some resins yellow over time, while others remain crystal clear.

- Working time: How long you have before the resin starts to gel.

Best Epoxy Resins for Casting and Table Projects

For casting and table projects, look for these qualities:

- Low viscosity for smooth pours

- Long working time for large projects

- High clarity and UV resistance

- Ability to cure in thick layers

Some top choices include:

- ArtResin for tabletops and artwork

- Liquid Glass Deep Pour for river tables

- TotalBoat TableTop Epoxy for bar tops and counters

But remember, the best epoxy resin depends on your specific project needs.

How to Properly Mix and Apply Epoxy Resin

Mixing epoxy resin and hardener correctly is vital for composite applications. For starters, resin options like coating resins are great for many applications. Epoxy resins may seem tricky, but they’re worth it— epoxies are used in plastic models or even in aerospace parts!

Most resins are generally mixed in a one-to-one ratio. But be prepared; mixing different types of epoxy requires care to get the right properties of the cured product. Developments in epoxy tech have led to thermosetting resins that withstand heat, used as adhesives in many epoxy systems.

Systems are used with specific curing agents used to solidify the mix. Plus, epoxy esters in certain formulations can enhance flexibility. Resins are typically chosen based on their groups of the epoxy and final use. These resin for all your crafting projects ensure durable, long-lasting results!

Step-by-Step Guide to Mixing Epoxy Resin

- Measure the resin and hardener accurately.

- Use the ratio specified by the manufacturer.

- Mix thoroughly, scraping the sides and bottom of the container.

- Avoid introducing air bubbles while mixing.

- If needed, divide the mixture into smaller containers to extend working time.

Tips for Applying Epoxy Resin Smoothly

- Work in a dust-free environment.

- Use a level surface for even distribution.

- Pour in a thin, continuous stream to minimize bubbles.

- Use a heat gun or torch to remove any surface bubbles.

- Apply in thin layers for best results.

Common Mistakes to Avoid During Application

- Incorrect mixing ratios: This can lead to soft or sticky spots.

- Inadequate mixing: Results in uneven curing and weak spots.

- Pouring too thick: Can cause excessive heat and cracking.

- Working in extreme temperatures: Affects cure time and final properties.

- Ignoring humidity: High humidity can cause cloudiness or bubbles.

What Are the Key Benefits of Using Epoxy Resin?

So, everyone’s raving about epoxy resin these days, and for good reason! Epoxy systems come with some sweet perks. They work wonders in laminate projects, thanks to their rad mechanical properties. The properties of epoxy make it perfect for resin systems and once you’ve got that cured resin, you’re golden.

The super versatile nature of epoxy resins means you can make epoxy resins fit for all your crafting needs. Whether you’re looking into epoxy composites or just resins used for coating, the high molecular weight ensures a strong finish. Wanna modify epoxy? No problem! This thermosetting epoxy material is super adaptable.

The best part about the epoxy resins produced is that there are tons of classes of epoxy to pick from. I mean, epoxy resins have been used for a while now, in tons of cool ways, like items coated with epoxy. Plus, epoxy resins also rock in enhancing the durability of whatever they touch.

From the different groups of the resin to the molecular weight resin, the use of epoxy resins is endless. The epoxy ring structure during resin production ensures that the epoxy resin properties stay impeccable. Yep, those terminal epoxy groups really do produce epoxy that stands the test of time!

Durability and Chemical Resistance

Epoxy resins are known for their exceptional durability.

They resist scratches, impacts, and wear.

Cured epoxy is resistant to many chemicals and solvents.

This makes it ideal for industrial and marine applications.

Epoxy coatings protect surfaces from corrosion and degradation.

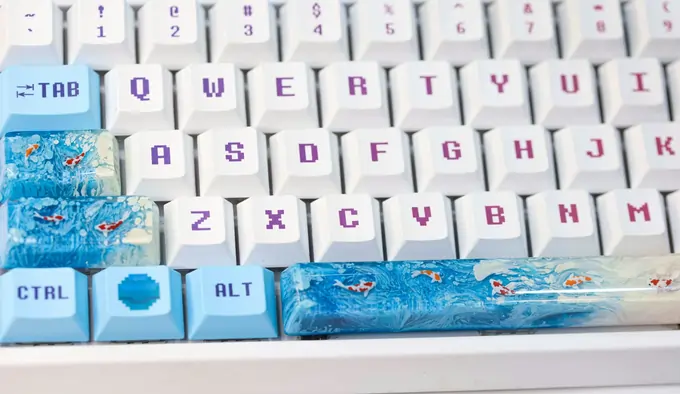

Enhanced Aesthetics and Gloss

Epoxy resins create a high-gloss, glass-like finish.

They can enhance the natural beauty of wood and other materials.

Color pigments can be added for vibrant, customized looks.

The clear finish allows for creative embeddings and designs.

The Versatility of Epoxy Resin in Different Applications

Epoxy resins are used in a wide range of applications:

- Flooring applications

- Aerospace industry

- Electrical applications

- Composite materials

- Marine coatings

- Jewelry making

- Artwork and crafts

- Tooling applications

This versatility makes epoxy a go-to material for many industries.

What Are the Safety Precautions When Working with Epoxy Resin?

When working with epoxy resin, especially for projects like epoxy resin for tables or crafting, safety is a big deal. Make sure you’re in a well-ventilated area because resins and curing agents can release fumes. Wear gloves because epoxies are also used in industrial applications and can be harsh on your skin.

Use a mask to avoid inhaling any particles when sanding solid epoxy resin. Keep your workspace clean and organized. Remember, epoxies can be used for many different projects, but safety should always come first. Always follow the manufacturer’s instructions and use proper protective equipment.

Personal Protective Equipment (PPE) for Epoxy Resin Projects

Safety should always be your top priority.

When working with epoxy, use:

- Nitrile gloves to protect your skin

- Safety goggles to shield your eyes

- A respirator mask for proper ventilation

- Protective clothing to cover exposed skin

Safe Handling and Storage of Epoxy Resin

- Store resins and hardeners in a cool, dry place.

- Keep containers tightly sealed when not in use.

- Work in a well-ventilated area.

- Avoid skin contact with uncured epoxy resins.

- Clean up spills immediately with appropriate solvents.

Environmental Considerations and Disposal

Epoxy resins can have environmental impacts if not handled properly.

Dispose of unused resin and hardener according to local regulations.

Cured epoxy is generally considered non-toxic.

However, dust from sanding cured epoxy can be harmful if inhaled.

Always follow manufacturer guidelines for disposal.

Epoxy resins have revolutionized many industries and creative fields.

Their unique properties make them invaluable in countless applications.

From DIY enthusiasts to aerospace engineers, epoxy resins continue to inspire innovation.

As you embark on your epoxy resin journey, remember these key points:

- Choose the right type for your specific project.

- Follow proper mixing and application techniques.

- Prioritize safety and environmental considerations.

With this knowledge, you’re well-equipped to create stunning epoxy resin projects.

So, what will you make with epoxy resin?

The possibilities are endless, limited only by your imagination.

Whether you’re crafting a river table or coating a boat hull, epoxy resin is your ally.

Embrace the versatility and beauty of this remarkable material.

Your next masterpiece awaits!